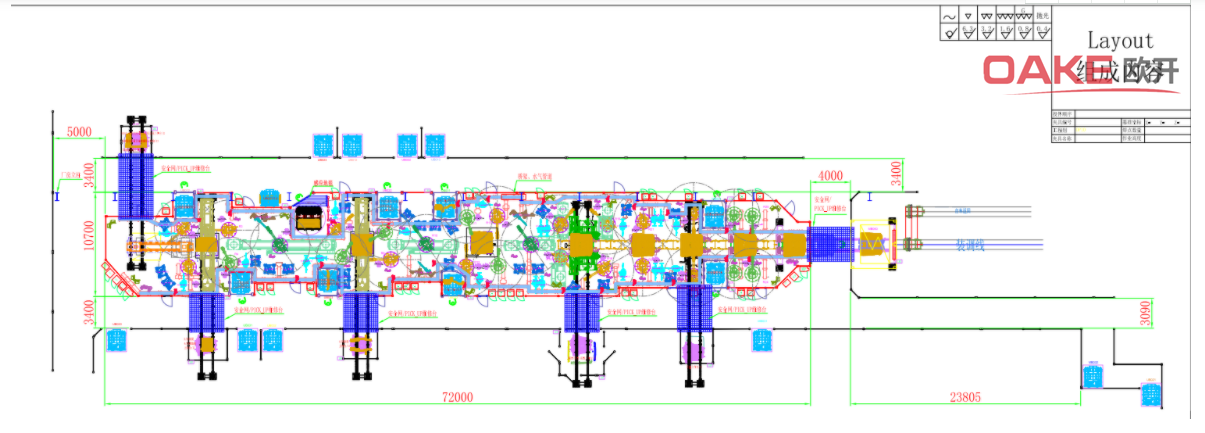

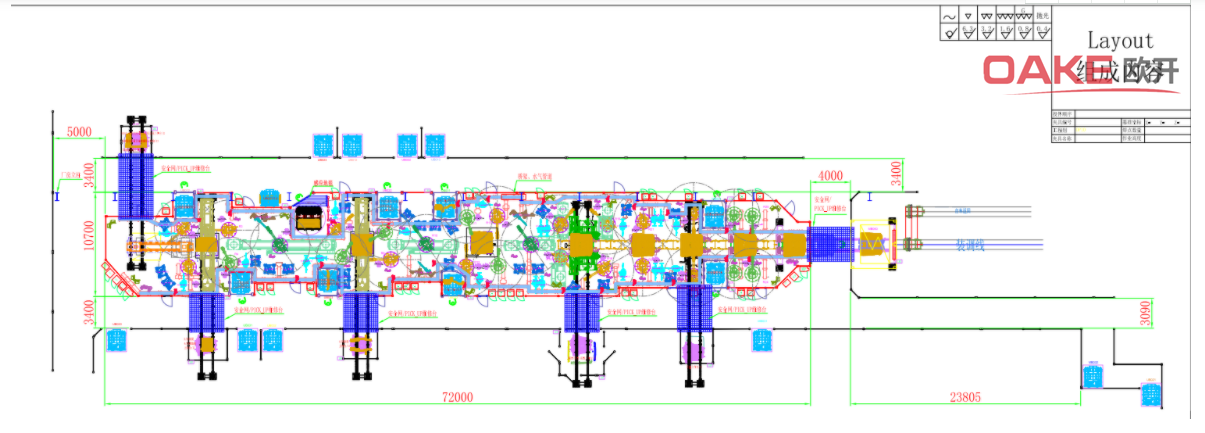

Project Description.

Cab automation transformation and capacity enhancement project, based on the customer's original cab robot spot welding line, add work station fixture overall automatic switching system, parts automatic loading system, PICKUP conveying system, workshop management system, etc. to achieve production line personnel reduction and information integration, greatly improving the automation rate. The floor area adopts robot handling to realize the transfer of parts between work stations, and the cab assembly area adopts the roller bed skid conveyor system. Capacity improvement is achieved by modifying the original layout and adding new robots and welding tongs.

Key Technologies.

Robotic automated spot welding, automatic upper part positioning system, production management system, picku conveying.

Results achieved.

Through the configuration of PICKUP, handling and parts loading robots, automated parts loading and parts automatic conveying were realized, and the production line staff reduction was achieved, resulting in increased production capacity and improved product quality. Establishment of workshop information management system.