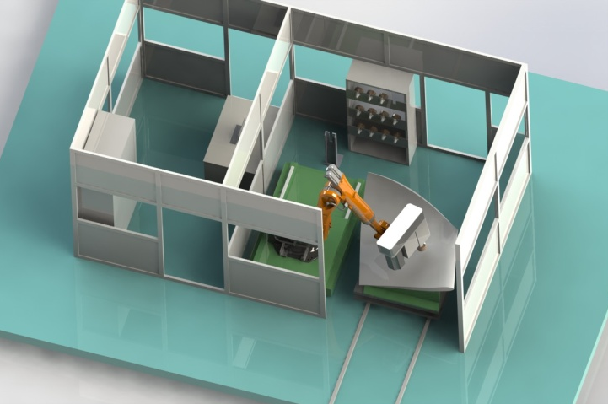

Project Description.

The surface of the polished workpiece is irregular free-form surface, which needs to be polished according to the design surface curve, and the material is mainly ultra-low carbon martensitic stainless steel or a small amount of austenitic stainless steel.

Key Technology.

Automatic scanning of the workpiece profile by 3D simulation, automatic model generation, automatic comparison and analysis of the design model, automatic positioning, automatic tool generation and automatic tool replacement.

Achieved results.

The grinding path coverage reaches more than 98%, and the unpolished residual area on the workpiece surface is <1% after grinding processing. Quality qualification rate reaches 99.5%, efficiency increases 10 times, quality improves 99.9%. No risk of occupational disease.