Project Description.

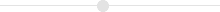

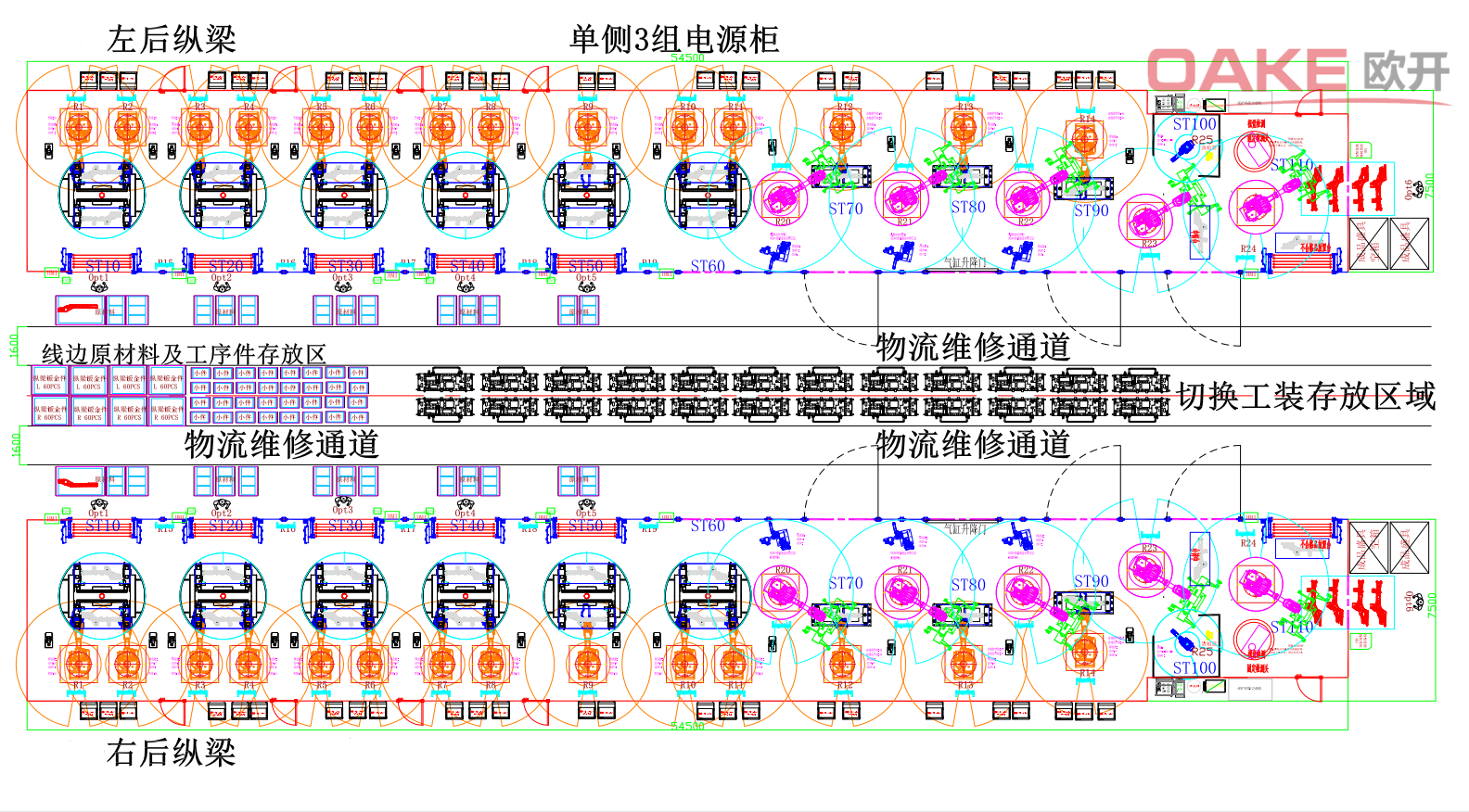

The automated production line of longitudinal beam and threshold integrates the technologies of spot welding, arc welding and laser detection. The longitudinal beam line adopts robot + turntable layout for positioning and welding stations, and robot + fixed welding clamp for floor welding stations, and robots are used for automatic loading and transporting of longitudinal beam semi-finished products between stations. The production line can quickly realize fixture switching through the rotary table quick-change fixture interface, which is compatible with the automated production of multiple models of longitudinal beam products.

Key technologies.

Robot automatic spot welding, automatic arc welding, high precision turntable, laser detection technology.

Achieved effect.

Automatic welding line and automatic handling, greatly reducing the number of production line operators, reduce personnel labor intensity. Product quality is greatly improved by means of automated equipment production and testing. The turntable and its quick-change interface ensure that the use cycle of the equipment is much larger than the product production cycle, and the quick-change switching fixture can be used to put new products into production without the need for large-scale transformation of the production line.