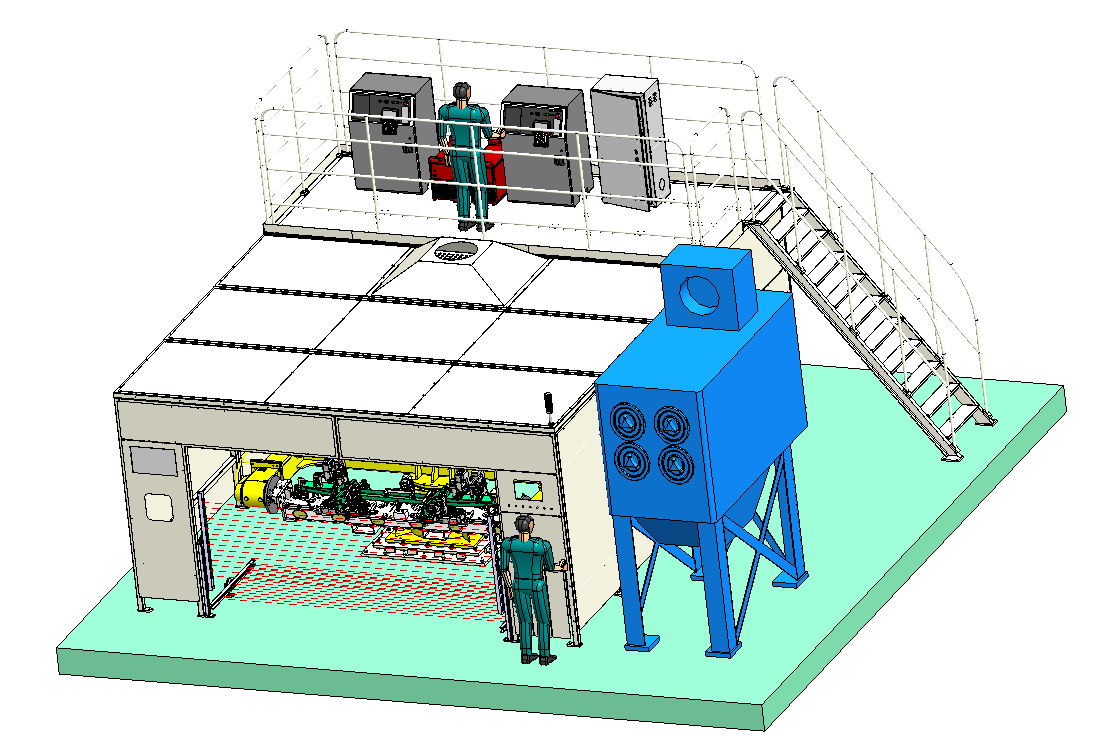

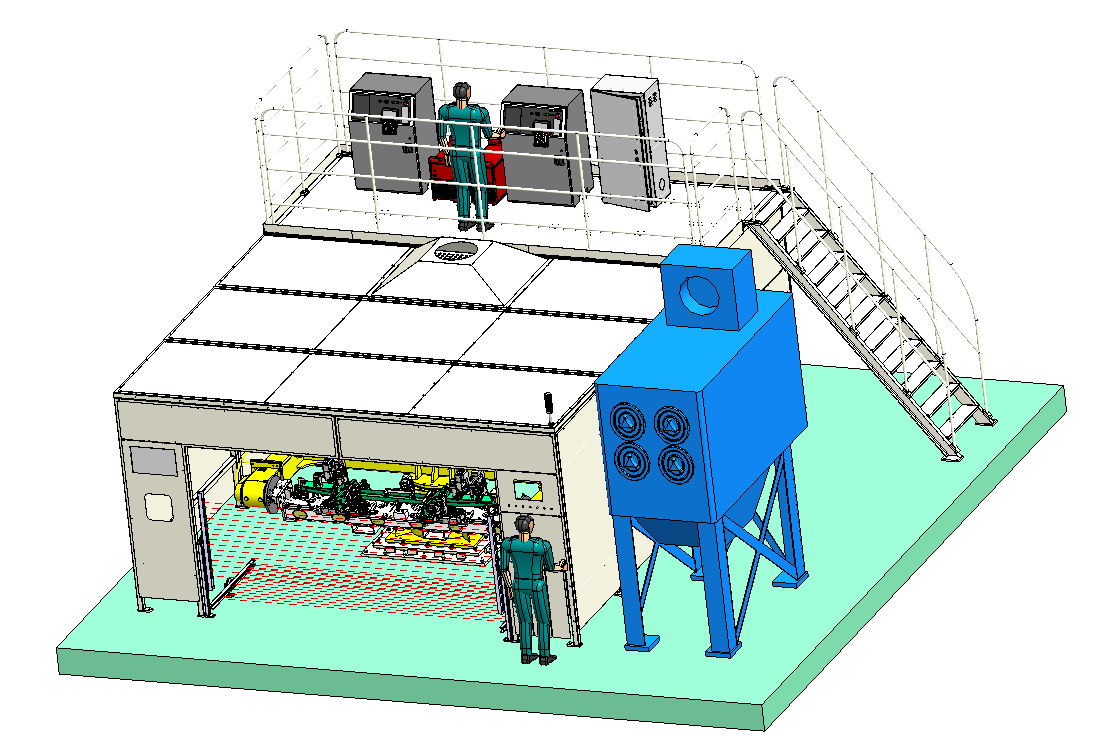

Project Description.

The welding system adopts double robots arc welding, horizontal back shift machine, assembly on one side and welding on the other side in the workstation, the upper part is equipped with dust-absorbing hood and dust-absorbing pipeline, and dust-removing equipment is configured.

Project effect.

Efficiency increased by 4 times, qualification rate increased by 25%.

Technical features.

Multi-robot coordinated welding, man-machine coordinated operation, man-machine platform sharing.