Project Description.

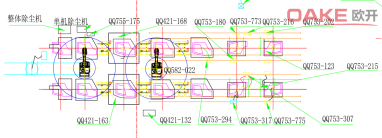

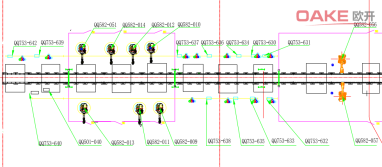

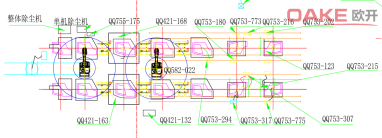

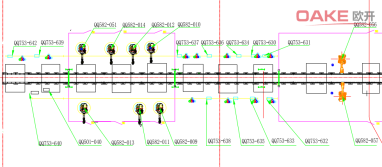

Update the J5 door and main welding line robot to realize the welding of J5 door assembly and cab assembly (13 models), to meet the requirements of function, quality and production schedule; the project is a turnkey project, we are fully responsible for the project layout, simulation, robot design, manufacturing, procurement, installation and commissioning, personnel training, production accompaniment and after-sales service, etc.

Key technologies.

Robot automated spot welding, production line capacity improvement, welding quality improvement, intelligent information transformation.

Achievement.

Automated welding line capacity improvement, the beat from 178S to 132S, greatly improve the production line capacity; welding quality improvement, further optimize product quality; intelligent information transformation, reduce the number of production line operators, reduce personnel labor intensity, improve convenience; at the same time complete the main welding line cab 13 models of common line, greatly improve the compatibility of the line.